Stakeholders at all levels in almost every industry continue to develop a more keen awareness of the importance of business sustainability. Six Sigma leaders who possess specific sustainability training can offer multiple benefits and specialized skills to help increase triple bottom line performance across industry lines. For emerging Six Sigma professionals, it is important to be aware of these trends and incorporate an understanding of Six Sigma and sustainability into future leadership management training goals.

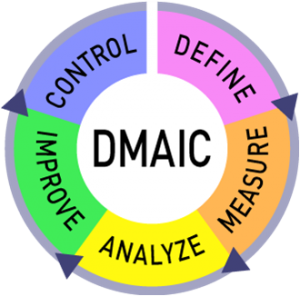

Applying DMAIC Principles to Sustainability Goals

Six Sigma strategies can be used as an effective framework to drive sustainable changes, including an improvement in triple bottom line performance related to water use and energy consumption. One of the bonuses of making changes that lead to more sustainable business practices is that they can also help to streamline manufacturing and business processes, saving resources as well as money.

Six Sigma strategies can be used as an effective framework to drive sustainable changes, including an improvement in triple bottom line performance related to water use and energy consumption. One of the bonuses of making changes that lead to more sustainable business practices is that they can also help to streamline manufacturing and business processes, saving resources as well as money.

Consider the case study of Kahiki Foods in Gahanna, Ohio. In December 2008, the company had a problem. They began to receive a hefty surcharge from local authorities because of their poor water quality – mainly due to an excess of biological waste entering the sewer system. Although there were a few metrics used to determine water quality, one stood out over the other – biological oxygen demand (BOD). The surcharge resulting from data collected by this metric comprised over 70% of the resulting fees. The total bill for subpar water quality surpassed $200,000 in 2009.

How DMAIC Strategies Reduced Kahiki’s BOD by 70% Within a Single Year

Hiring qualified Six Sigma consultants to help Kahiki improve their water quality and reduce resulting fines brought about significant positive results over a relatively short period of time. By following Six Sigma methodology, the organization was able to isolate the processes that needed to be adjusted to achieve better water quality.

Here’s an overview of how they applied the familiar DMAIC framework to achieve these impressive results:

- Define – The problem was easily defined because the biological oxygen demand data accounted for over 70% of the charges. The source of the waste was also evident, originating from inefficient floor drain management.

- Measure – The consultant and Kahiki management teams reviewed data including previous and current production rates and sewer consumption trends. They examined data indicating pounds of waste entering existing plant drain baskets. They also collected data related to the solid wastes found at other key areas, such as at the sump and the interceptor.

- Analyze – By including management in the analysis process, a set of key questions were used to identify where improvement was needed and what the next actions should be. “Hot spots” were indicated and benchmarks were set using best practice industry data from other companies.

- Improve – The process of improving the water quality required several stages. Employee education was needed to support the new procedures. New equipment was purchased to better separate waste, and drains that were no longer needed were closed off.

- Control – To continue improvements, on-going employee education was implemented. In addition, metrics were put in place to monitor progress, and were posted to show improvement. Communication was improved between workers and management regarding waste handling challenges.

Kahiki had begun as a nationally acclaimed restaurant in the 1960’s and enjoyed international acclaim into the early 2000’s when they transformed into a high quality manufacturer of frozen Asian meals. In 2009 they were named Food Plant of the Year.

Partnering with Six Sigma consultants assisted this long-standing company in reaching the goals that needed to be met so that it could continue to set industry standards and produce a high quality product, minimizing its impact on the surrounding environment.

By the end of fiscal year 2010, Kahiki had reduced their BOD by over 70%. At the end of the project, the team felt that a 90% reduction was possible. Improving their waste management processes also resulted in an over 60% reduction in total suspended solids (TSS) which has also contributed to corporate savings.

Currently the company continues to grow with a strengthened commitment to environmental responsibility locally, as well as a commitment to ocean conservancy internationally.