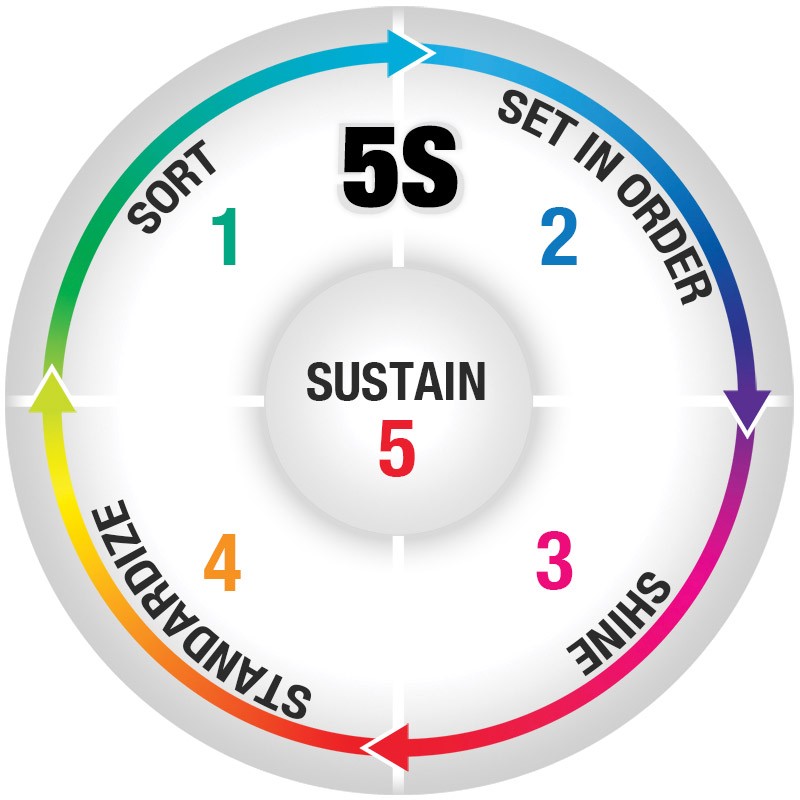

5S – Sort, Straighten, Shine, Standardize, Sustain

5S derives its name from five Japanese terms beginning with the letter ‘S’. A conscientiously-applied program of 5S creates a workplace suited for visual control and Lean production. Collectively, the five S’s (detailed below) outline how to create a workplace that is visibly organized, free of clutter, neatly arranged, and sparkling clean. The 5S system is often a starting place for implementing Lean operations.

![Back to [Lean Six Sigma] Basics](http://d3tl80hy6t5toy.cloudfront.net/wp-content/uploads/sites/4/2019/03/06051336/back-to-basics-compressor-700x420.jpg)