Lean, Six Sigma and the Theory of Constraints (ToC) rank among the best strategies for creating positive change and optimizing processes within a company, according to a recent column in CIO magazine. All three approaches foster process optimization that can give organizations an edge in an increasingly competitive business environment.

CIO columnist Bob Lewis recently wrote about the rankings and process optimization specifically as it relates to IT leaders who want to better understand the methodologies used by business managers. However, the strategies can work in any type of department in any industry.

He noted that choosing the right methodology depends on which dimension of process improvement IT leaders want to improve. There are six categories: Fixed cost, incremental cost, cycle time, throughput, quality, and excellence. Lewis wrote: “You can only optimize around no more than three of them; the ones you choose have tradeoffs; and each methodology is designed to optimize different process dimensions.”

Using The Right Methodology for Optimization

In listing the most popular options for process optimization, Lewis focuses on what organizations can accomplish with Lean, Six Sigma (or a combination of the two known as Lean Six Sigma) and the Theory of Constraints. Each focuses on different areas of process improvement. The following offers a brief overview of each.

Lean

Lean’s primary focus is eliminating waste. Every step of a process is considered with the customer in mind. Project teams eliminate any actions that do not improve a product or benefit the customer. Toyota made the principles of Lean famous through the Toyota Production System. Lean also focuses on issues such as improving quality (including use of Voice of Customer) and reducing cycle time.

One of the main components of Lean (and Six Sigma, as well) is the idea of continuous process improvement. A project team does not come in, “fix” things, and then the process is over. A Lean approach invites people from all levels of an organization to participate in an ongoing, systematic approach to process improvement.

Six Sigma

Six Sigma focuses on eliminating variation from processes that lead to mistakes and errors. It started in manufacturing, but it’s become popular across all industries. The main focus of Six Sigma is on finding the root causes of issues that lead to defective products or services, and then using proven tools and techniques to eliminate the problem.

The most popular strategy in Six Sigma is DMAIC, which stands for define, measure, analyze, improve and control. It provides a detailed approach to assessing any type of operation and optimizing it. Six Sigma’s focus on improving quality also leads to a reduction in costs.

Theory of Constraints

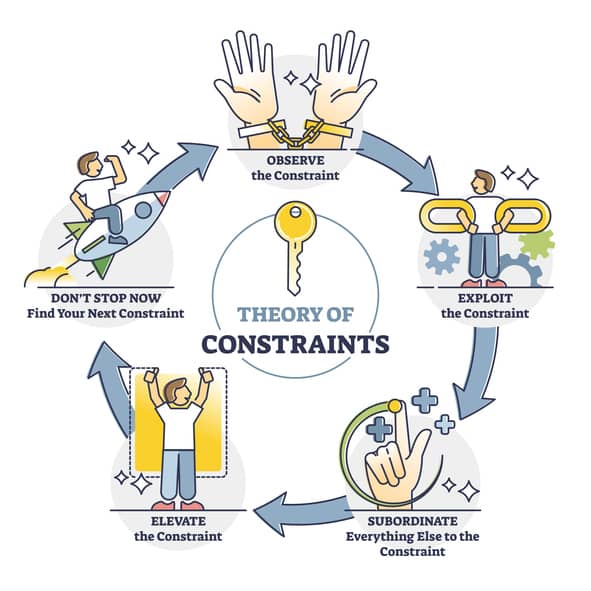

The Theory of Constraints came from the mind of Eliyahu Goldratt, one of the most influential business thinkers and consultants in the last 60 years. The theory involves finding the weakest link in the chain of operations needed to complete a process. Goldratt said businesses should focus on throughput and finding the bottlenecks that constrain it. By increasing throughput and reducing cycle time, businesses can increase profit. ToC is especially effective for businesses having difficulties keeping up with demand.

Goldratt considered increasing profits – as opposed to slashing budgets – as the best strategy to improve a business. He advised using the simple but effective process in ToC – identifying and eliminating constraints, then repeating the process – as the best way to rebuild struggling businesses or make a good one great. Lewis refers to ToC as “the best process optimization methodology nobody’s ever heard of.”

Interested in more content like this? Check out our Six Sigma Glossary for articles on common process improvement terminology.