Chocolate candy covered in a hard shell is not included on a list of Six Sigma quality improvement tools, but maybe it should be. In the 1980’s, the rock band Van Halen used M&M’s to cultivate a myth of unbridled superstar excess – and to assure the safety of their stage shows.

In the early 1980’s Van Halen toured the country putting on some of the most elaborate stage shows fans had ever seen. When the band arrived at the venue, lead singer David Lee Roth would immediately make his way backstage to the catering table looking for the one item that made all the difference, a bowl of M&M’s. If there were no brown M&M’s in the bowl the concert would go as planned. If Roth saw brown M&M’s, chaos and destruction would quickly ensue.

In the early 1980’s Van Halen toured the country putting on some of the most elaborate stage shows fans had ever seen. When the band arrived at the venue, lead singer David Lee Roth would immediately make his way backstage to the catering table looking for the one item that made all the difference, a bowl of M&M’s. If there were no brown M&M’s in the bowl the concert would go as planned. If Roth saw brown M&M’s, chaos and destruction would quickly ensue.

David Lee Roth became notorious for inflicting thousands of dollars of damage on the green rooms that were unfortunate enough to contain the wrong kind of candy. If he saw brown M&M’s, Roth would unleash havoc on everything around him – overturning buffet tables, destroying furniture and kicking holes in walls.

Eventually this story became a rock legend, proving that that rock stars indulge in wild, excessive and often destructive behavior, and made frivolous demands just because they could.

Outrageous Ego or Pure Genius?

Years later when David Lee Roth was asked about the brown M&M’s, he cast the story in a different light. Roth admitted that the antics, triggered by the wrong kind of candy, had more to do with business than with ego.

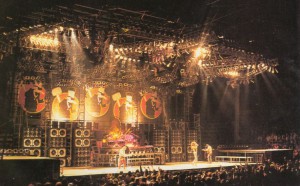

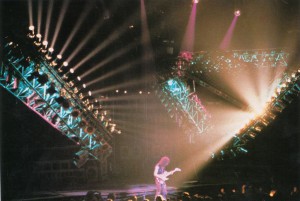

Van Halen’s stage shows were bigger, bolder and more ambitious than any other act touring at the time. Most tours could transport their stage, sound and lighting equipment in three semi-trailers, but Van Halen required nine. If the shows were going to meet fan expectations, promoters needed to make extensive modifications to the venue before the band and its crew arrived.

This advanced work was spelled out in great detail in the concert rider that Van Halen sent to every promoter. It was the promoter’s responsibility to ensure that the venue met standards specified in the rider so that the concert could go as planned. Sadly, not all promoters lived up to this responsibility. Some didn’t even read the concert rider.

The stakes were higher than just a disappointing performance. Poor preparation could cause problems as serious as a collapsed stage or a toppled light tower that would put fans, the crew and the band members in danger.

The stakes were higher than just a disappointing performance. Poor preparation could cause problems as serious as a collapsed stage or a toppled light tower that would put fans, the crew and the band members in danger.

How could Van Halen tell if promoters had prepared the venue as the rider specified? Every promoter assured them that the venue met the contract standards, even the ones that didn’t. Van Halen could have had their road crew run a line check at every venue, but that was too expensive and time consuming.

Then Roth thought of a way to test how closely the promoters followed the concert rider. He buried a clause in the middle of the document that stated the promoter would forfeit the entire show at full price if he did not provide a bowl of M&M’s backstage with the brown ones removed.

It was brilliant.

In a glance at a candy jar Roth could tell how much attention the promoter had paid to the contract. If promoters were paying close enough attention to notice the candy requirement, they had most likely followed the technical requirements as well. Promoters who hadn’t noticed that providing the wrong color of candy would cost them the full price for the entire show had probably also overlooked important technical and safety requirements.

When he found brown M&M’s, Roth would unleash his famed fury of destruction backstage. Then he would order the road crew to run a check on the venue. Whenever they saw brown M&M’s in the bowl, they found potential technical and safety issues were commonplace.

What other ways can you think of to see the quality of a complex project at a simple glance?

Did you enjoy this article? You might also like: Six Sigma, Beer and Industrial Quality Control